While Apple’s success is often associated with a special focus on customer needs, high quality and innovative design, part of the truth also lies in an extremely sophisticated supply chain. However, in the context of global shortages of logistics and chip capacity, wait times for new iPhones have now also hit record highs. In order to understand why we should order our Christmas presents in good time this year, we have taken a look at the iPhone supply chain and explain where the problems lie.

While the iPhone is designed in California, a large part of the components are not manufactured or processed in the USA. Apple relies on suppliers from more than 40 different countries on six continents, sends components to manufacturing plants to be assembled, and then ships the finished iPhones around the world. Each iPhone is made up of hundreds of individual parts, most of which are manufactured by a different supplier each time – for example, parts of the camera are made in Japan, some battery elements are made in China, and components to measure the iPhone’s acceleration are made in Germany. So Apple’s supply chain is exposed to the following risks:

- Can all suppliers provide their components on time in the promised quantity with satisfactory quality?

- Can the components be shipped quickly to the next production step?

- Can the finished iPhones be shipped to the stomer?

While Apple, just like other companies, is prepared to deal with the failure of a specific supply chain, few companies are prepared for a relatively rapid failure of entire supply chains. In recent months, for example, all the risks described above have occurred at the same time:

Can all suppliers provide their components on time in the promised quantity with satisfactory quality?

After a global supply and demand shock related to the covid pandemic, many companies reduced their inventories in order to generate liquidity on the one hand and to avoid storage costs in case of a prolonged recession on the other hand. Following an extremely rapid and strong recovery in global demand, these companies were thus faced with very low inventory levels, which led to increased demand for components such as chips. This subsequently overloaded not only producers in the chip industry, but also the logistics industry, which had also scaled back capacity after global trade came to a virtual standstill in 2020.

Can components be shipped quickly to the next production step?

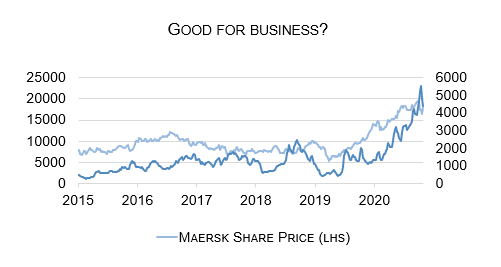

The congestion of global logistics capacities becomes very clear when looking at the development of freight rates, here exemplified by the Baltic Dry Index (source: Bloomberg). While companies from the shipping industry were able to profit strongly from increased container rates, companies from the manufacturing industry had to struggle with rising transport costs or even a lack of access to transport capacities. Given a globally ramified network of suppliers, such a scenario also affects companies like Apple.

Can the finished iPhones be delivered to the customer?

While most iPhone production takes place outside the U.S., the U.S. is an important sales market for Apple. If the company manages to manage the first two risks, delivering the product to the customer could prove to be the final challenge. For example, at times in mid-October, more than 100 ships were waiting off the California coast because the most important two ports on the U.S. East Coast (Los Angeles & Long Beach) did not have sufficient capacity to unload the cargo. Yet these two ports alone are responsible for 40% of all U.S. imports by sea. In addition, there is a shortage of truckers to take the cargo inland afterwards. To make matters worse, full warehouses and congested freight yards do not make logistics any easier.

While we usually refrain from investment recommendations and timing advice in this publication, we would like to make an exception to the rule in this issue. Given the current onset of a “perfect storm” for global supply chains, our advice for the coming holiday season is to:

- getting an early start on gift buying.

- an investment in lots of time with loved ones after Christmas celebrations marked by social distancing.